Electric Forklift

South Africa vs Pakistan: Forklift Battery Market & Application Comparison

Table of Contents

As core power components of material handling equipment, forklift batteries directly impact operational efficiency, costs, and reliability in warehousing, logistics, and manufacturing. This article compares the forklift battery markets of South Africa vs Pakistan, analyzing application trends, challenges, and opportunities, with insights into Baufar’s lithium battery advantages.

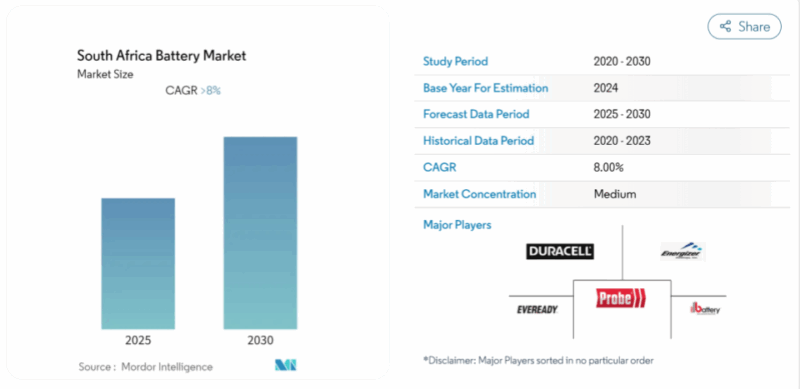

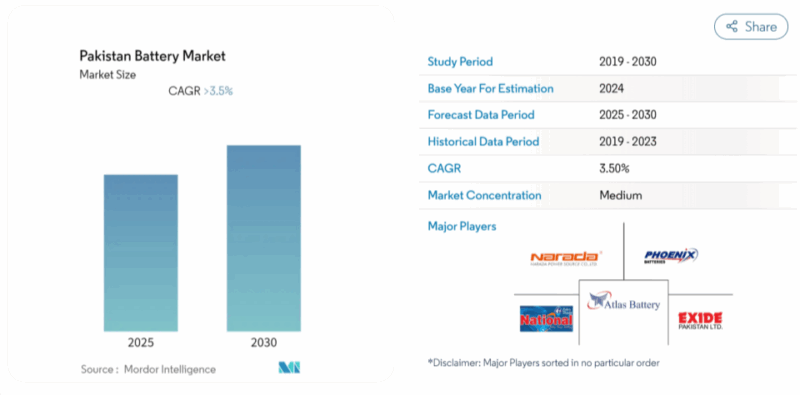

Market Overview: South Africa vs Pakistan

-

South Africa: The industrial battery market (including forklift applications) shows robust growth, driven by warehousing and e-commerce logistics. Electric forklifts dominate new acquisitions, with heightened demand for reliability, endurance, and fast-charging capabilities.

-

Pakistan: Steady expansion in industrial and backup power batteries fuels opportunities. Lithium-ion adoption is accelerating as infrastructure upgrades and cost-conscious transitions from lead-acid batteries gain traction.

Both markets present significant potential for forklift battery upgrades.

Source: mordorintelligence.com

Source: mordorintelligence.com

Application Scenarios & Demand Profiles

| Aspect | South Africa | Pakistan |

|---|---|---|

| Primary Drivers | Logistics scalability, multi-shift operations | Cost efficiency, infrastructure modernization |

| Technology Adoption | Rapid shift to lithium-ion for productivity gains | Gradual transition from lead-acid to lithium |

| Key Needs | Fast charging, low maintenance, long cycle life | Affordability, durability, operational simplicity |

Forklift Battery Technologies & Trends

-

Lead-Acid Batteries:

-

Pros: Low upfront cost, established technology

-

Cons: Frequent maintenance, slow charging, shorter lifespan

-

-

Lithium-Ion Batteries (e.g., Baufar):

-

Pros: High power density, rapid charging, 3-5x longer cycle life, zero maintenance

-

Cons: Higher initial investment

-

Baufar leverages premium cells (e.g., EVE, CATL) and smart BMS to deliver enhanced safety and longevity for industrial vehicles.

Market-Specific Recommendations

-

South Africa: Prioritize lithium-ion solutions for high-throughput logistics hubs to maximize uptime and total cost of ownership (TCO) benefits.

-

Pakistan: Implement phased lithium adoption, starting with critical operations, while leveraging lead-acid for budget-constrained scenarios.

Strategic Guidance for Procurement Managers

-

Cycle Life & Durability: Lithium-ion outperforms lead-acid in intensive applications.

-

Charging Efficiency: Minimize downtime with lithium’s 1-2 hour charging capability.

-

Service Support: Verify local technical assistance and supply chain resilience.

-

Brand Reliability: Partner with certified providers like Baufar for seamless OEM integration.

Conclusion

While South Africa’s market favors immediate lithium adoption for productivity gains, Pakistan’s gradual transition reflects cost-sensitive pragmatism. The universal trend, however, shifts toward lithium-ion forklift batteries for superior TCO and operational flexibility. Baufar’s tailored solutions offer both markets a pathway to electrification excellence—balancing performance, safety, and scalability.

Featured Forklift LiFePo4 Battery

80V Forklift Battery

Forklift Lithium-ion Battery 80v 404Ah for Toyota 7FB30-7FBJ35

48V Forklift Battery

Forklift Lithium Battery 51.2v 404Ah for Still FM-X

48V Forklift Battery

48V 519Ah Lifepo4 Lithium Battery for Heli CPD20/25-GB2/GD Forklift

80V Forklift Battery

80V 404Ah Lifepo4 Lithium Battery for CPD30/35-G1/G3 Forklift

80V Forklift Battery

80V 560AH Lifepo4 Lithium Battery for HELI CPD35-GD2

80V Forklift Battery

80V 600Ah LiFePO4 Lithium Battery for NICHIYU FBC25/30P Forklift

48V Forklift Battery

48V 201Ah Lifepo4 Lithium Battery for NICHIYU FBRM13H-70 Reach Truck

48V Forklift Battery

48V 225Ah Lifepo4 Lithium Battery for HYUNDAI 10/13BR Forklift